- In this section you will find all the information available for download. Select the area you are interested in from the menu on the left. The software section contains both the latest and old releases of all software including software for archived products.

- Download the latest drivers, software, firmware, and diagnostics for your HP products from the official HP Support website.

- KV Series Hardware Manual - Emtron; KV Series Ethernet Pinout - Emtron; KV Series Rev2 ECU Wiring - Emtron; KV Series EFI Relay Wiring - Emtron; KV Series Power Distribution Wiring - Emtron.

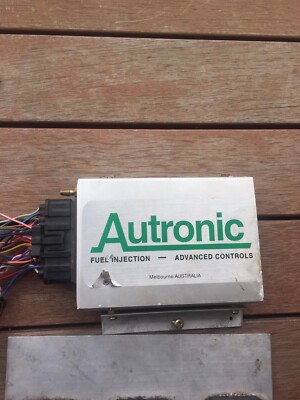

The installation can be broken down intotwo main sections. One is the modifications that are carried out to accommodatethe physical installation of the unit, relative actuators and sensors,and removal of stock parts no longer required, which will come under thecategory of Preparation. The other is the rewiring of the stockengine wiring harness to accommodate the Autronic, which will come underthe category of Rewiring. You can click on any of the smaller imageson this page to view them larger. My advise is to read this write up firstand then proceed, this will help to save you from wasting your time puttingback on something, that you realize later should have been left off, whenyou reach another section.

VemsTune Software (Current) Click Here to Download Current Software - UPDATED; Click Here to Download the Serial-USB Driver Program; VemsTune Manual (e-mailed to customers). Downloads View or download various technical documents related to our products. Customer Inquiry We promise customer satisfaction with our high quality customer service. Global Autonics Find out more about our global network, with market activity in over 100 countries.

Preparation

The first stage isto decide where you are going to mount the Autronic SMC ECU. I chose tomount it in the same location as the stock ECU.

RemovalOf The Stock ECU & Fabricating A New Mounting Plate

Before beginningthis installation disconnect the negative cable from the battery. The ECUis located behind the centre console on the flooring. Simply peel back thecarpet and you will see that it is secured by two nuts on the left handside, and one on the right hand side. On the left hand side you will seethree connectors plugged into the ECU, and another connector plugged intothe 'circuit opening relay' (located on ECU). Unplug all these connectors,then remove the three nuts securing the ECU in place, and then remove theECU from the left hand side. It's tight under there so some shifting todifferent angles while removing may be required. Youare now ready to use the stock ECU for a reference to make a mounting plateto secure the SMC. You will also need (unless you want to fabricate yourown) to remove the three brackets that are attached to the stock ECU, soyou can use them on the new mounting plate you are going to make. Usingthe pictures in this section as a guide, you should easily be able to figureout how to go about fabricating your new mounting plate. Once the Mountingplate is finished,and the SMC ECU is attached, there are two more things to add to it, themain relay and the reluctor interface (refer to the 'Package'section for info on the reluctor interface). To attach the reluctor interfaceuse the bracket for the circuit opening relay that was attached to thestock ECU. Using two cable ties, attach the reluctor interface to the bracket,and then bolt the bracket to the left rear screw that attaches the SMCto the mounting plate (refer to the larger picture for clarification, ifyou need it). The next thing to attach is the SMC's main relay. To do thisI made a bracket (refer to the larger picture), and attached it to theleft front screw that attaches the SMC to the mounting plate. The finalstep is to remove the protective plastic piece that is on top of the stockECU, and put it on top of the SMC ECU, You will want the protective pieceto overhang at the front, so it protects the connector as well. Click hereto see a picture of the SMC ECU installed.

RemovingParts No Longer Required

A few stock partswill not be needed by the Autronic. They are as follows, the Air Flow Meter,the Turbo Pressure Sensor (MAP), the Injector Resistor Pack, the Fuel PumpResistor, the Idle Speed Control Valve, and the Cold Start Injector.

Air Flow Meter:TheAutronic SMC is a speed density system and as such uses as it's main input,manifold pressure, air temperature and engine speed (rpm) to determinefuelling and ignition requirements, which makes the Air Flow Meter (referredto from here on as the AFM) obsolete. Removal of the AFM is very straightforward, so there is no need to go into any great detail. What you willneed to do is add a performance air filter with a 3 inch opening. The wayI did mine, was to use a short length of 3 inch pipe, and attached thefilter to one side, and then attached the stock intake hose to the otherside. You will have to get the side of the pipe you are attaching to thestock intake hose flared a bit, as the hoses inner diameter is slightlymore than 3 inches. To get an idea of what I did, click hereto view a picture of my engine bay.

Turbo PressureSensor: The Turbo Pressure Sensor (referred to from here on as theMAP sensor), isn't needed by the SMC, but it is needed for the stock boostgauge in the instrument cluster. If you don't care about the stock gauge,you can simply remove the sensor (the gauge will read full boost all thetime). If you want the gauge to work, you will have to find a 5v DC supplyfor the sensor. This wasn't a problem for me, as the ERL System2 waterinjection comes with a 5v DC supply for a MAP sensor. Another possibleway is to tap into the supply from the SMC wiring harness, for the ThrottlePosition Sensor, however, I strongly recommend that you check withthe dealer you purchased your Autronic from, before attempting touse that feed.

Injector ResistorPack & Fuel Pump Resistor: The injectors in the ST185 are low impedance,and the stock ECU uses saturated drivers, which requires that the 12v DCfeed for the injectors must run through a resistor pack. The SMC ECU usesthe better peak and hold type drivers, which can control the low impedanceinjectors, without the use of a resistor pack. The pack is located justunder the battery behind the radiator. You will need to remove the batteryin order to gain access to the bolt, to remove the pack. Note that thereis also another resistor on the same bracket as the injector pack. Thisis the fuel pump resistor, and was used by the stock ECU to reduce voltageto the fuel pump for low load driving conditions. This too, is no longerrequired. This part is dependant on whether you wish to join the wire fromthe Autronic main relay straight to the pump, or use the existing stockwiring. I used the stock wiring as it is the right gauge, and was the easiestmethod. In order to bypass the fuel pump relay, you will need to locatethe relay box next to the alternator, and remove the fuel pump relay (theonly yellow relay). You now have to bridge two of the four vacant terminals.If you are standing facing the car, jumper the top left terminal with thebottom right terminal. This set-up allows you to connect the wire for thefuel pump from the SMC main relay, to the blue wire with the orange stripe,that is located in the connector that was plugged into the circuit openingrelay.

Idle Speed ControlValve: The Autronic does not control stepping motor type Idle SpeedValves (referred to from here on as the ISC) , which as such makes theISC obsolete. Some of you are probably thinking that idle quality willbe bad without this, but this is not the case. The Autronic has an 'IdleIgnition Table' that supplies a very stable idle. My car idles between950 rpm and 1050 rpm, but quite smoothly. It is actually just as smoothas when it had in the stock ECU. To remove the ISC you will need to removethe intercooler, and then remove the throttle body. To remove the throttlebody, you must first remove a bracket that supports the throttle body. Thebracket has two 10mm bolts attaching it to the cylinder head, and two 12mmbolts attaching it to the throttle body. Then remove all hoses, the ISCconnector, the Throttle Position Sensor connector, and the acceleratorcable from the throttle body. There are four 12mm bolts holding the throttlebody to the plenum chamber, remove these, and remove the throttle body.You are now ready to remove the ISC. The ISC is held onto the bottom ofthe throttle body with four screws. These screws will be in tight, so usethe proper size screwdriver. I prefer to use a ratchet that I have, thatcomes with various screwdriver bits. A ratchet allows you to use more downforce, and gain better leverage, so avoiding the probability of strippingthe head of the screw.

At this stage youhave the ISC disconnected, and are ready to build a blanking plate forthe bottom of the throttle body. I used aluminium to build a plate. Usethe ISC valve to mark out the outline (it is not necessary for it to followthe same shape, it can just be rectangular), and positions of the fourholes on the aluminium. Then cut the blanking plate out of the aluminium,using a hack saw, or some type of saw. I don't recommend snips for this,as they tend to make the aluminium curl, and you want the blanking plateto be flat. Once the plate is cut out, drill your four holes, and fileaway any imperfections. If you are like me you can then proceed to bringthe plate to a nice shiny finish. Start by using 400 sandpaper, and workyour way up to 2000 sandpaper, and then polish with Brasso. The final stepis to secure your blanking plate to the throttle body. You will need tosource shorter screws, as the stock screws are too long.

Another thing I removedwas the piping (one piece, see picture) for the ISC valve, coolant hoses,vacuum supply for power steering pump, and A/C idle up VSV. Thisis not the easiest part to remove, reaching the bolts holding it on ishard enough, but working it out from between the intake manifold and thestays, requires lot's of manoeuvring. You really don't need the coolanthoses that lead to the ISC. These only serve to keep the throttle bodywarm, which you really don't want on a turbo car. When you remove the pipingyou will be left with two open coolant lines (that used to run to the throttlebody), so attach a hose from one end to the next, or you could blank themoff. For the power steering valve, I ran a hose straight from the valveto the connection point on the back of the plenum chamber, and the otherhose I ran along the intake manifold stays, to my source of pre turbo air.You need to source pre turbo air for the A/C and power steering valve,so run a hose from the stock location on the first intake hose (Hose nearerthe air filter), and connect it to them using a 'Y'. You will also findthat the pipe attached to the bracket by the distributor (the bracket withthe clips for the spark plug wires), is not need anymore.

Cold Start Injector:I never bothered to enquire whether the Autronic could control the ColdStart Injector (referred to from here on as the CSI), because I feel itis not necessary. The Autronic has 'Post-start Enrichment Multiplier',and 'Post-start Enrichment Time-out' maps, as well 'Warm-up EnrichmentMultiplier' and 'Warm-up Accel. Enrichment Mutilplier' maps, so all yourneeds for cold start fuel are covered.

The first thing youneed to do is remove the fuel line going from the fuel rail to the CSI.This is a banjo connection on both points, and the banjo is held with a10mm bolt.Remove the line from the fuel rail and the CSI. The CSI is held in placein the plenum chamber with two bolts, simply remove these two bolts, andremove it. The next step is to build a blanking plate similar to the oneyou made for the throttle body. You can use the CSI gasket for a template.When you have finished your blanking plate, attach it to the plenum chamber(you can re-use the old gasket, as it is a metal gasket and should sealback fine). You will also have to blank of the opening in the fuel rail.Todo this I used a spacer with two perfectly flat sides (the same thicknessas the banjo), two new copper gaskets, one on either side, and used theoriginal bolt to secure it to the fuel rail.

Parts ThatMust Be Added For The Autronic

There are only threemain things that have to be added, the Air Temperature sensor, the BoostControl Valve (referred to from here on as the BCV), and the stock ignitormust be replaced with a Bosch Ignition Module. The only other things thathave to be added is relays, depending on what features you use. I usedthe 'Fan Control' to control the radiator fan, the 'On/Off' map to controlthe T-VIS, and the 'Fan 2' to control a cold start valve to supply extraair to the engine when it is cold. The last one is achieved by using the87a terminal of a relay. I set the 'Fan 2' to come on at 45 degrees Celsius,and turn back off at 10 degrees Celsius (a temperature the coolant wouldnever drop back to). When the vehicle is started and the temperature isbelow 45 degrees Celsius, the relay is off, and the terminals 30 and 87aare bridged, which results in power to the valve, thus supplying extraair. At 45 degrees Celsius, the relay is switched on, and terminals 87(which has nothing attached to it) and 30 are bridged, which sends 87aopen circuit, and the valve turns off.

The BCV can be installedanywhere. I chose to install it on the bracket that supports the air filter. Thislocation is relatively close to the wastegate hose connection and the turbohose connection. The Bosch ignition module was located in the same placeas the stock ignitor. Remove the stock ignitor by removing the bracketfrom the firewall, which is held by two 10mm bolts. Remove the ignitorfrom the bracket, by removing the two screws securing it to the bracket.The Bosch module requires a heat sink, so I used a piece of aluminium,and then drilled the holes in the aluminium, and the stock bracket, forthe Bosch module to attach to them. The Bosch Module will come with a whitesilicone grease on the bottom of the unit, do NOT remove this grease.Click hereto view a picture of the engine bay, where you will be able to see theBosch Ignition Module.

The Air Temperaturesensor (referred to from here on as the air temp sensor), is probably themost involved addition, and will require a machine shop to make a fittingfor it. The sensor will need to be mounted in a position in the plenumchamber. The intake manifold has two plugs either side of it, so I decidedto use the location for the plug on the left hand side of the manifold.In order to use this space the plug must be removed from the manifold.Removal should be done when the engine is cold. You will need a large screwdriver or something similar with the flat end almost the same thicknessas the lip on the plug. Place the screwdriver on one particular spot, Ichose the top, and using a hammer, start to hit the screwdriver forcingthe top to go inwards. It helps to move the screwdriver a little to theleft and give it some hits, and then a little to the right, and give itsome hits, then back to the middle, but don't go to far left andright, you want to keep your efforts concentrated on the top of the plug.What will happen is that eventually the plug will start to shift on it'saxis. It's like taking a quarter between your fingers, and holding oppositeedges, and tilting it. When the plug tilts far enough you can use a pliersto pry it out. Try and not damage the plug too much. The edges will getpretty badly messed up from the pounding, but don't worry about that.

Take the plug andair temp sensor to a machine shop, and get them to make you a piece frombillet aluminium, thick enough for the threads of the sensor, that is slightly,and I mean very, very, slightly larger in diameter than the stock plug.Then get them to tap a hole in the new plug, for the sensor. The sensor'sthread is tapered, and as such the machine shop that made mine, createda very nice concave design on the inside of the plug, so that when thesensor was screwed in, the very edge of the threads was flat with the concave,and the sensor part protruded nicely out. Itis also important that the new plug have a tapered inside edge just likethe stock plug. When you get home place the new billet aluminium plug inthe freezer, and leave it there for several hours. Get everything you aregoing to need ready, like hammer, a socket that will fit nicely on topof the new plug (so as not to damage the threads), and some thread locker.Spread some thread locker around the inside of the hole in the intakefor the plug, then retrieve the new billet piece from the freezer, andstart to push it into the hole. It should go in about half way, if it looksway to big, do not start, return to the machine shop, and ask them to decreasethe diameter slightly. If it goes in rather good, about half way, justpast the taper, then place the socket over it, and hit the socket witha hammer to force it into the hole in the plenum. Hit a few times and checkall the edges. If it is protruding more on side, then concentrate yourhammer hits on that side, then check again, and repeat this process, untilit is flat with the intake manifold. Put a little teflon tape on the threadsof the temp sensor, and screw it into the new plug. Don't install it totight, as aluminium is soft and you could strip the threads. It shouldbe just tight enough that you can't unscrew it by hand.

Rewiring

Decidingon How To Approach The Rewiring

There are two choices when it comes tothe rewiring. You can cut the wires at the location of the stock ECU, andthen solder the wires for the Autronic harness to the relevant stock wires,and then do variuos ccorrections to the harness in the engine bay. I didnot choose this approach, as I feel it is too much of short cut, not tomention it would make trying to figure out how certain wires were connectedin the stock harness, very difficult. The other choice is to rebuild thestock harness. I went this route for a couple reasons. The first beingthe ability to actually trace where wires were going, and which wires connectedback up to which wires, and the second being that it would replace mostof the older stock wiring harness wires.

RemovingThe Harness

Go back to the locationwhere the stock ECU used to be located, and you will notice two large connectors,a white one, and a grey one, disconnect them. There will also be a clipholding the stock wiring along the flooring on the left hand side. If youlook towards the top of the clip, you will see it is attached to the protrusionof a stud. At this location on the clip, you will notice a little tab.Rotate the tab about 90 degrees, and then pull the clip off. This willmake the harness inside the vehicle ready for removal. Your next step isto remove the harness from the engine bay. Start on the alternator sideof the engine bay. Remove the following connectors, as well as remove theconnectors from any clips or brackets. The CAT temperature sensor, theradiator fan switch, the A/C compressor, the oxygen sensor, and the alternatorconnectors. Under the alternator, you will find a 10mm bolt holding theharness, remove it. You will also find a 12mm bolt on the side of the alternatorbracket holding the harness in place, remove this as well. In order toget the harness out from this location, you will need to remove the alternator/ACcompressor belt. Once the belt is out of the way, you can remove the harnessfrom it's location by the alternator. The next section of the harness isheld in place near the right hand side of the valve cover, by two tabsthat simply slip over the protruding ends of the bolts that hold the timingcover in place. You are now ready to deal with the area by the fuel rail.

The harness is housedin a plastic piece between the fuel rail and intake manifold. Before physicallyremoving it, some connectors have to be disconnected. The most difficultones are the Turbo VSV (if you are still using it), the T-VIS VSV, theknock sensor, and the ground strap. All of these are located under theintake manifold, and access from the top of the engine is impossible. Jackup the front right hand side of the car, place a jack stand under the vehicle,and remove the wheel. You will have to put your hand through the openingfor the steering rod ends, and feel your way around until you find theknock sensor connector, the T-VIS connector, and the ground strap (whichwill be held to the manifold by a 10mm bolt), then disconnect them. TheTurbo VSV is probably easier reached by approaching it from the left handside of the engine bay through the top. Once located disconnect it. Nextdisconnect the distributor connector, and the speed sensor connector. Thisclears the area under and around the intake manifold of all connections,so go ahead and remove the connectors for the injectors. The cold startinjector, ISC valve, and throttle position sensor connections will be alreadydisconnected, since you removed the throttle body earlier. Remove the 10mmbolts holding on the brackets attached to plastic piece housing the wiring,remove the fuel pressure regulator, and remove the oil cap (I usually placea piece of cloth in the hole to stop anything large falling in the holefor the oil cap). You will now have enough room to remove this sectionof the wiring harness. Some manoeuvring will be required to get the plasticpiece out from between the intake manifold and fuel rail.

In order to removethe harness completely, there are more things that have to removed anddisconnected. Let's start with the disconnections first. Disconnect theturbo pressure sensor connector, the ignition coil connector, the ignitorconnector, the three way pressure switch connector (located near the diagnosticbox on A/C line) and the two connectors near the diagnostic box, as wellas removing the diagnostic box itself from the bracket it is located on.There will be a rubber boot bolted onto the firewall where the enginewiring harness comes out, it is held in place by two 10mm nuts, removethem. On the left hand side strut tower, you will see a clip that holdsthe harness to a bracket. Pry the tab on this clip and slip it off thebracket. Near this same location, below the wiring harness, you will seea connector with two wires, disconnect it. At the end of this bracket youwill see another clip on the wiring harness, do the same for this clip.Unplug the reverse light switch connector (located on top of gearbox),the large connector for the oil pressure switch, coolant temperature sensor,and cold start injector time switch, the connector for the coolant temperaturesensor (for the gauge in dashboard, single wire), and the coolant temperaturesensor (for fan control with A/C on, single wire). The connectors for thefuel injector resistor pack and fuel resistor pack (the later is not partof the engine wiring harness) will have already been disconnected. Disconnectthe connectors for the starting motor. There is another plastic piece thatis attached to a bracket on the gearbox, that has to be removed. One onside (side closest to engine) it will have a clip with a tab, pry up thetab and remove. The other side will have a circular tab that pushes througha circle hole in the bracket. The tab has a protrusion top and bottom thatmust be pushed together, in order to push it out of the bracket. Next youwill now need to remove the hose from the fuel filter, and the two coolanthoses leading to the heater core.

Your next task willbe to open up the bottom of the main fuse/relay box (located next to battery).The battery should have already been removed to gain access to the resistorpack's bolt, so you will have more than enough space. Remove the top cover,then remove the bottom cover. This box will be fairly brittle from age,so expect some tabs to break, and be aware that you may have to find away to hold the bottom on, should most of the tabs break. The section withthe four main fuses, slides out from the bottom of the box. There is atab on either side that must be pushed to allow the fuse section to slidout. Once this is out, take note of which connectors on the bottom of thebox are from the engine wiring harness, and remove them. The battery positiveterminal should already be off, as the battery would have been removed.The last connection is a round single wire connector, that is down on theflooring where the battery would sit, disconnect it.

Lift the harnessout of it's position, and get it to a point where you can startto pull the harness section that inside the car, out from the hole in thefirewall. Once everything is clear, lift the entire harness out of thecar. When the harness is out, lay it on a large space such as the floor,and spread it out similar to how it is in the picture. The next phase isto make sure you have a reference for getting the lengths of the wiresyou will be adding, and the length and angle of the different points wherewires will branch off. The easiest way, is to have a spare harness, touse as a guide. The other way is to photograph the harness, scan the photoand print it. Then take all the measurements from the harness, like lengthfrom harness to connector, length from one branch to another, etc., andnote them on the print out.

DisassemblingThe Harness

Now it's time todisassemble the harness. You only need to disassemble from the ECU connectorsto the plastic piece that holds the wires for the injectors, etc. Thepiece that goes over the valve cover and beyond, does not have to be disassembled.Also the rubber boot that attaches to the firewall should not be removed,or moved from it's location. This is a tedious process, and be assuredthat you will probably be able to lift a 5lb weight without closing yourfist, your hands will be that sticky when you are finished. To be on thecautious side you could place the parts, tubing, clips, etc., from thewiring harness in the order they were in, on the floor. I didn't botherwith this, as this was the second time I rebuilt a GT_Four harness, soI was familiar with where they came from and the order.

RewiringThe Harness

There are a few thingsthat need to be covered before you begin rewiring the harness. One is thetools and supplies you will need. I have listed as complete a list of toolsas I can think of, however you may find you need something that may notbe on the list. One thing not mentioned that you should definitely haveis wiring diagrams for the car. The Chilton's manual is for U.S. cars,but the wring diagrams are adequate. Needless to say the Toyota Workshopmanual will work.| Solderingiron | 60/40flux solder | Heatshrink tubing |

| Electricaltape | Wirestripper | Wirecutters |

| Exactoknife | Multi-meter | Setof small screw drivers |

| Crimpingtool for connectors | Canof Electrical cleaner | 600sand paper |

Soldering:If you are not familiar with soldering, I suggest you practice on somepieces of wire before actually soldering connections on the harness. Themain thing you want to avoid is a cold joint. A cold joint is formed whenthe wire itself has not reach a high enough temperature or the wire iscontaminated, and the solder has not spread between it. Cold joints generallytend to look very dull. The proper technique for soldering is to melt avery small portion of solder on the soldering iron tip, place the tip ofthe soldering iron on the wire you are going to solder, and leave it therefor a few seconds. This will heat the wire up. Then position the solderbetween the iron and the wire, and the solder should immediately startto spread along the wire easily. The finish will usually range from lookingclean to very shiny. Another problem is corrosion or contaminants on thewire. The flux in the solder will take care of mild contaminants, but insomething like the harness, you really want to ensure a good joint. I usuallyflatten the wire and lightly pass it between 600 sandpaper, then flattenfrom a different angle and repeat. Then I spray a healthy dose of electricalcleaner on the wire, as preperation for soldering.

Autronic Driver Download

Solder Joints:Thefirst stage is to strip the ends of the two wires you are going to solder.Then cut the needed length of the correct thickness heat shrink tubing,and slide it onto one of the wires. Slide it as far away from the pointwhere you will be soldering. If it is too close, it may start to shrinkfrom the heat of the soldering process. Next twist the two wires togetherneatly, and proceed to solder them. Slip the heat shrink tubing over thejoint, and using a heat gun, or a cigarette lighter, heat the tubing, untilit shrinks to nice tight fit, taking up all the contours of the solderjoint. The next stage isn't really necessary, but I like overkill in situationslike this. Cover the heat shrink tubing with electrical tape. I also tryto make sure all my solder joints are in the main section of the harness,where they will not be exposed to bending and flexing, like would be expectedclose to the connector.

GettingStarted

You should now havea nicely laid out, stripped stock wiring harness laying on the floor. Youwill need to prepare the Autronic SMC harness. To do this remove the blacksleeve that comes with it, and remove all the cable ties that are attached,except the one for the main relay connector. Place the SMC connector nearthe stock ECU connectors (give yourself about 3 extra inches of lengthfrom the stock ECU connectors), and position all the wires from the Autronicharness in the opposite direction of the stock harness.

Autronic Driver Download Windows 10

The ActualRewiring

I use a process thatmakes the job simple. I decide on a connection and then remove that wirefrom the stock harness, and then add the relevant wire from the Autronicharness to the stock harness. For example, you want to connect the negativewire for cylinder 1 injector from the Autronic harness, so you cut thestock wire for cylinder 1 injector at the point you desire the joint tobe, and remove it from the harness, and then remove it from the ECU connector(there is a clip that can be pryed with a small screwdriver to pull thewire out of the stock ECU connectors). You then hold the wire from theAutronic harness for cylinder 1 injector about 3 inches away from the Autronicconnector, and using the old wire, determine the length of wire required,adding about an inch and a half extra for the joint, and cut the wire,then make the joint. Before you can finish the harness, you have to completethe installation of all the things you are using, and that must be used,so you can determine the correct length of the wires to reach them. Thewiring diagram found further down the page, should make it easier for youto figure out the correct connections. One thing worth noting, is thatin order to keep the stock tachometer and A/C working, you will need toinstall a 1 Kohm resistor (10% tolerance) between the negative side ofthe coil, and the wire leading to them.

PicturesOf the Completed Wiring Harness

Autronic Driver Download Software

Click on any of thepictures to view a larger image

WIRINGDIAGRAM

The colours of thewires from the Autronic connector are accurate, however these diagramsare for my reference, so the colours of other components are based on thecolour of the wires I used, and also the colour of the stock wiring wherejoined. When referencing this diagram, the connector should be viewed fromthe back, where the wires come out.

Click herefor a link to a wiring diagram for a twin coil setup, with Flat-Shift,on the 3S-GTE

More information on a twin coil wastedspark setup can be found here

Autronic Driver Download Pc

This page was createdby Dennis Heath.

If you should wishto ask a question about the GT-Four/All-Trac, you can join the GT-FourMailing List, where I, and many others with GT-Four's, might have youranswer. For information on joining go to http://www.onelist.com

Autronic Driver Download Windows 7

Pleasenote that I am not a mechanic by trade, and that any information offeredon this web page is free and without guarantee. Should you choose to performany of the procedures listed on this site, you will be doing so of yourown free will, and I will not be held responsible or liable for any damagesthat might occur from using information obtained here.